曾經創業失利開計程車、媽媽擔心到哭,高雄油料小處理廠永瑞董事長林修安,為什麼能讓國際石油巨頭搶買台灣夜市攤販、餐廳不要的廢油,變成全球航空業減碳救星?

永瑞董事長林修安(中)把夜市廢油變乾淨原料,還以DGM為品牌,開發智能回收機台,背後意思是地球只有一個,因此「別去火星(Don't Go to Mars)」。圖左為研發長吳侑峻、右為財務長鄭力維。圖片來源:楊雅晴攝

永瑞董事長林修安(中)把夜市廢油變乾淨原料,還以DGM為品牌,開發智能回收機台,背後意思是地球只有一個,因此「別去火星(Don't Go to Mars)」。圖左為研發長吳侑峻、右為財務長鄭力維。圖片來源:楊雅晴攝

4月初,油輪「Golden Sky」在台中靠港,要載著台灣生產的1000多噸低碳工業用油,送到芬蘭石油公司Neste位在新加坡、最新擴產的全球最大再生煉油廠,做成永續航空燃料(SAF,Sustainable Aviation Fuel),直接添加進飛機引擎,比傳統燃油減少八成碳排量。

波音執行長卡爾霍恩直指,SAF是航空業「達成2050年淨零碳排的唯一解方。」根據國際航空運輸協會(IATA)估計,到2050年SAF將幫全球航空業減碳65%,等同每年需要4490億公升產量。而截至去年,產能連零頭都不到,全球不過3億升、加油點才40多個,新產能一開,馬上被訂走。

台灣能幫全球航空業減碳的救星,源頭是位在高雄的永瑞實業,它從全台餐廳、夜市攤販、速食店的油鍋中搜集廢食用油,精煉成SAF的原料。

這些油得通過歐盟33項品質檢驗,在國際永續發展與碳驗證(ISCC)要求下,還得提供可追溯的產源履歷:誰處理、誰清運,乃至哪個店家提供,每滴油都得一清二楚。

相較老大哥承德油脂把廢食用油做成生質柴油 ,這家年營收約3.5億的小公司選擇不同的路:把廢食用油做成乾淨的原料。

不只賣給Neste,永瑞也賣進荷蘭殼牌、英國BP,進到韓國、馬來西亞、新加坡、歐洲等再生煉油廠,每年出口一萬多噸,是台灣唯一通過各國際煉油廠認可、提供SAF原料的廢食用油處理廠;今年初更拿到全台首張廢食用油碳足跡ISO認證。

永瑞在台南新吉工業區的廠區,設立著不鏽鋼做的儲油槽,搜集全台的廢食用油。(楊雅晴攝)

永瑞在台南新吉工業區的廠區,設立著不鏽鋼做的儲油槽,搜集全台的廢食用油。(楊雅晴攝)

「我的客戶從來沒有斷過,」49歲的永瑞董事長林修安講話徐緩,眼神發光。一輩子做油,這是他東山再起的二次創業。

林修安在台灣海洋大學讀研究所時,就鑽研廢食用油轉化生質柴油技術,在工研院當了5年研究員後創立靖騰能源,在台灣生質柴油政策喊卡之前,曾和承德油脂、新日化並列三大供給中油的生質柴油廠。

當時的靖騰不到30人,一年營收可達10億。但創業沒幾年,他就因理念不合被迫離開董事會。

人生跌了一大跤,林修安沒有回工研院謀職,而是繼續待在創業地高雄,在酒店前排班開計程車,就這樣開了一年多。

基隆老家的兩老以為他就此一蹶不振,爸爸告訴他,媽媽擔心得哭了。

「我沒有喪志,我是在計劃,」林修安從學生時期就兼差開計程車賺學費,駕駛座是他靜下來思考的空間。如果回工研院,就是承認這輩子在商場失敗;但若要再創業做拿手的生質柴油,建處理廠要有規模效益,投入資金至少上億起跳,又會跟國際大廠強碰。

他想到,在研討會上認識的國外生質柴油同業,最常一起抱怨的就是原料品質參差不齊。經常整個貨櫃高達三成是水和油泥,還有雜七雜八的溶劑等雜質,肉眼無法判斷品質好壞,一投料就堵塞管線,得拆機器清理乾淨才能重啟,大大影響投料轉換率和生產效率。

林修安以前也常退貨不良原料,他直覺,商機就在這裡。

「我和北中南的這些小蜜蜂(廢食用油清運業者個體戶的俗稱)從靖騰開始認識,非常熟,可以把我龜毛的個性拿出來,提供乾淨的原料給買家。」

他湊了150萬資金,聯繫上國際生質柴油廠CEO,開始在全台買廢食用油,經過品管、檢驗,成為市場上少數有把關品質的的廢食用油出口商。

他賭對了。2013年永瑞成立,第一年就賺錢,營收9000多萬,員工含他只有3個。2019年,永瑞設置處理廠拿到許可,林修安的龜毛更加充分發揮在精煉過程上。

廢油精煉的學問多。除了處理掉雜質、水分、氯離子和有機溶劑,速食店交來的油含有炸雞骨頭溶出的鈣和磷,算在總金屬含量裡,也得壓下來。永瑞品質做到位,精煉後的低碳生質基底油,可作為從切削油到壓延油等各種工業用途。這次,國際石油巨頭的生意來了。

他對自己的油非常有信心。第一次飛到荷蘭和殼牌談採購合約,被質疑報價為何比中國貴了一些,他的回應是,「那你直接跟他們買好了。」

「我做過生質柴油廠老闆,我清楚原料非常關鍵,」林修安分析,中國原料轉換率不到九成,還得花成本處理大量油泥,拖累稼動率;而永瑞能做到轉換率95%,換算下來沒有比較貴。殼牌自此成為永瑞的客戶。

2021年,永瑞推出智能回收機台,店家自行交油秤重後,馬上按照回收牌價由第三方支付,銀貨兩訖,還有錄影存證。

永瑞在台南花園夜市、高雄青年夜市以及連鎖速食店等地布建了18台,收油成本大減八成。「資料上到區塊鏈,客戶要raw data(原始資料)都可以提供!」林修安自豪地說。

台灣廢食用油除了交給清潔隊及清除機構回收外,約有四成透過小蜜蜂,一桶桶聚沙成塔回收而來。林修安最希望用這台機器改善他們的工作環境。

永瑞將智能回收機台放在夜市、速食店,減輕收油負擔,客戶也能查看完整數據。 (楊雅晴攝)

永瑞將智能回收機台放在夜市、速食店,減輕收油負擔,客戶也能查看完整數據。 (楊雅晴攝)

草創時期因人力不足,林修安曾親自開車收油。一桶油16公斤,他從KTV到餐廳,白天到黑夜一桶桶來回扛,衣服濕了又乾,收油一週後大病一場。

「這工作真的非常非常非常辛苦,」他細數,收油不僅是風吹日曬的勞力活,也常行程延誤,遇到店家忙碌或打烊,當天收不到油又得擇日安排出車,很沒效率。「我就想,我不是工研院出來的嗎?不是技術背景的嗎?有沒有比較聰明的方式?」

他從五金行買了幾根萬能角鋼、一個幫浦,聘了一個工程師,土法煉鋼一步步改良,最後做出智能回收機台。不僅放在夜市讓攤商交油,也能進餐廳配耐高溫管線,接在油炸鍋下抽油。

這讓小蜜蜂的收油工作更快速且彈性,也讓客戶有所依循。「只要涉及減碳,都要有紀錄可供查證,」協助永瑞在高雄夜市設置機台的高雄市環保局副局長黃世宏觀察。

林修安心裡總是有這群被稱為「小老闆」的收油小蜜蜂。永瑞草創不久就遇到黑心油風暴,回收油牌價暴跌剩四分之一,林修安跳過層層中間商,用原價買,又提供永瑞開發的app給小蜜蜂使用,讓收油不再是無跡可循的現金交易,一切資訊透明且開放。

「與永瑞合作就被當作永瑞的一份子,」杰奇企業社負責人陳忠義也是一名小蜜蜂, 在靖騰時期即與林修安合作,「他是全台灣唯一直接對上小蜜蜂的處理廠,其他都是靠中盤商。」

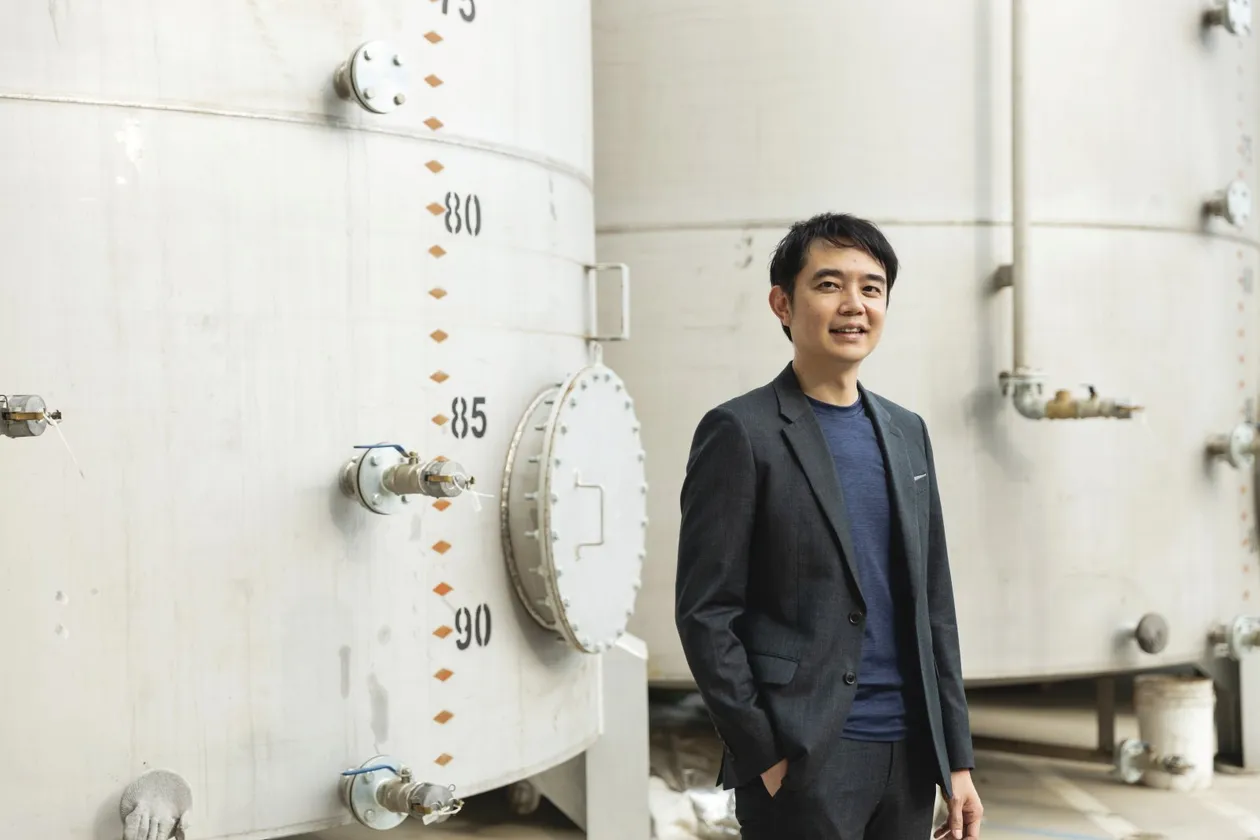

林修安期望來自台灣的乾淨原料,能優先助攻台灣航空業者減碳。(楊雅晴攝)

林修安期望來自台灣的乾淨原料,能優先助攻台灣航空業者減碳。(楊雅晴攝)

目前與永瑞合作的小蜜蜂約20個。林修安初次見面都先從道德聊起,十幾年前他結識陳忠義時,也先大談廢油流入食物體系的危害。陳忠義觀察,有些小蜜蜂為了賺錢,做法有時偏差,會參雜高酸油、飼料油甚至是病死禽畜的屍油,必須從人品管控合作品質。

當系統和機台在台灣證明可行,整廠輸出甚至到海外設合資公司都有可能。

「像義大利廢油才回收30%,就能用這套設備跟系統把油給逼出來,」林修安盤算著,在全球SAF大缺之時,也未嘗不可藉乾淨原料作為談判籌碼,要求國際SAF煉油廠優先供給台灣航空公司。

不過,永瑞革新回收效率的新商業模式,得先證明台灣能逼出更多油。

據環保署估算,台灣一年產生約8萬噸廢食用油,業內人士觀察,這還餵不飽既有大廠如承德、勝一化工旗下和勝倉儲的產能。永瑞能否在搶油大戰中贏過大廠,是接下來業務擴張的挑戰。

創業初期,林修安曾被母親責罵,放著工研院好好的工作不做,創業創到去收油。問他,去年受邀進總統府領金舶獎,兩老放心了嗎?「反正他們就是愛你才會嘮叨,」龜毛的兒子講到家人,一時靦腆了起來,「我們就是好好地做,不要讓他們失望或丟臉啦。」

(責任編輯:王儷華)